Stone carving and masonry

‘The actual tools of the trade centuries . . . . technology is still unable to match the stone mason's craft, which is still one of hand, eye and experience.'

- Tim Neller, Cathedral Works Organisation

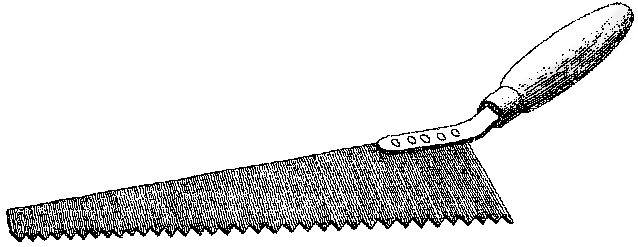

The stone carver's tools include: an iron hammer, which resembles a carpenter's hammer in shape, but is smaller; a hard wood mallet; and chisels, such as the point chisel for use on harder varieties of stone, and the punch chisel for use on softer stone. The excavation of stone is done using a hand saw, ‘plugs and feathers’, a ‘walling hammer’ and a ‘Jadd Pick’. Excavated stone was extremely heavy and boats were commonly used to transport it until the railway revolution of the 19th century.

The journey of the stone from hewn block to finished product is undertaken by masons with various levels of skill and might involve the ‘stone mason’, the ‘banker mason’ and the ‘fixer mason’. The skill of the mason when making stone blocks was to ‘dress’ them square and true, so that they would fit together with tight joints of less than 1/4”.

The qualities of a particular type of stone and, consequently, the uses to which it is put as a building material depend largely upon how it was formed millions of years ago.

Carving stone should be of a fine grain, and sufficiently soft to admit easy working. The bottom layers of limestone, for example, are fine grained and therefore suited to carving. The Bath stones of England and the Caen stone of France have often been used for internal work, while oolite - of which limestone is the main variety - is suitable for external carving.

Carving is often done after the stone has been built into position, the face having been left rough - ‘boasted' - and projecting sufficiently for the design to be executed.

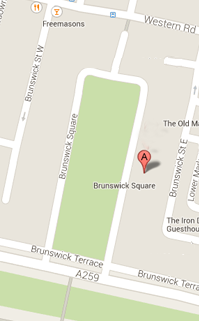

Besides being carved for decoration, stone played an important role providing structural support, as lintels for example, and it was often used for paving, as with Brunswick Square and Terrace. There are only a few examples of elaborate stone carving to be seen on Brighton’s domestic Regency architecture, although in other locations it is not unusual to find numerous town house facades decorated with white limestone detailing.

Stone can be divided into three categories: sedimentary, metamorphic and igneous.

Sedimentary rocks

Sandstone and limestone are examples of sedimentary rocks, formed by the deposition in water of sand and the remains of small marine animals. Limestones, commonly used during the Regency period, vary according to the site from which they are sourced and the strata in which they are located.

The ‘Oolites’ are the best of the limestones, Bath and Portland stone are from this group. York stone is a sandstone quarried from sites in the north of England. This type of stone is very hard wearing and can be obtained in enormous blocks, two factors that make the stone ideal for paving and large scale exterior work.

Above: Masons working at column

Metamorphic rocks

Metamorphic rock is formed by the great heat and pressure of volcanic action and movement of the earth’s surface. This variety of stone is perhaps best illustrated by slate, originally a sedimentary rock, but one which was changed by metamorphic action into a laminated stone. The resulting stone is very dense, has a low permeability and can be easily split to produce the roofing materials with which we are all familiar. Slate gives good coverage without excessive weight, a feature greatly liked by Regency designers who hid their shallow pitched roofs behind the fashionable raised parapetan architectural device employed in the Brunswick Town area.

Many Brighton town houses were roofed in blue slate from the Penrhyn quarry in North Wales, an attribution made possible as slate from this quarry carries small green discolourations that are unique to this site. After the 1760s, slate shipped from Wales and Cornwall almost entirely replaced clay tiles in urban speculative housing development.

Slate was also hung vertically on battens fixed to exterior walls to form a weatherproof cladding while inside the house, it was sometimes used for shelving or chimneypieces.

Above: a stone masons coping saw.

In Brighton there are also some good examples of Welsh slate being used underfoot, rather than overhead. The distinctive large blue Welsh slate flagstones laid on the pavements of Wykeham Terrace in 1822 can still be seen today. Roof slates were traditionally fixed with iron nails to timber battens nailed onto the rafters, or fixed directly onto softwood planking which covered the roof and was called ‘sarking’ or ‘close boarding’. Where batons were used they were spaced or ‘gauged’ so that each slate would overlap the ones below, like the scales of a fish, to form a two-layer roof covering.

Marble is another example of metamorphic rock, fine grained and compact, it is an ideal material for decorative carving and was used extensively during the Regency for chimney pieces, table-tops, sculptures and tablets. Britain has no true marble stock, although George Bullock, the early 19th century furniture designer, made extensive use of ‘Mona Marble’ obtained from Anglesey in North Wales. This rock is, in truth, a deposit composed principally of magnesium silicate, but it was greatly admired for its coloration and markings which were said to resemble those of a serpent’s skin.

Igneous rocks

Igneous rocks are formed by the solidification of molten material beneath the earth’s surface, granite and flint are examples of this type of stone.

Granite is a dense and durable material, but extremely difficult to work. An example where this has been achieved can be found next to the Royal Pavilion where a statue of George IV rests on a plinth of squared and polished Cornish granite blocks.

Artificial stone

Artificial stone frequently appears in houses during the period. The most famous of these products was Coade stone, in truth, a ceramic product which offered the appearance of stone at a more competitive price. Coade stone was invented in 1769 and manufactured by the Coade family, at Lambeth, until the 1840s. The business was unusual in that it was almost entirely managed by female members of the family.

Many examples of this product still survive although the recipe and manufacturing process has, regrettably, been lost. We can find examples of its use in the Brunswick Town area, where small tablets of Coade stone form a component of the capitals which sit above the major columns and pilasters seen on the front elevations of large town houses. The Regency Town House at 13 Brunswick Square displays such Coade stone detailing.

If you are interested in further reading on this topic, these links will provide you with more information:

The stone carving blog; 'History of Stonecarving' by W. Daniel Dinsio

Ashby Stone Masonry's brief history of stonemasonry

BBC; British history of the medieval stonemason