R-EX data Building Materials

The front of the house is covered in lime render, which is a type of cement. The surface of the render has then been marked with horizontal and vertical lines, to make it appear like blocks of stone, a much more expensive material and one that is extremely scarce in this part of the country.

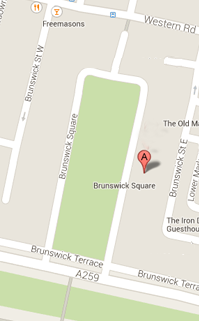

Behind the render is brick, which was widely used in historic Brighton. These bricks were made from clay, sometimes called ‘brick earth’, which was abundant due to an eight to ten metre seam of clay deposited on top of the chalk on which the town is built. The clay to make the bricks to build Brunswick Town was excavated and fired in the area of the garden in today’s Brunswick Square.

While the architect Charles busby specified that the front elevation should be made from brick with lime render covering, the other material used extensively to make Brighton houses is a type of flint and lime walling, known locally as bungaroosh, or bungaroush.

Bungaroosh was much cheaper than brick, and was used to make other parts of the building, including some of the party walls and rear elevation.

Bungaroosh is a local material, made from lime derived from burning the chalk that forms our downland, mixed with flints which are hugely abundant and found as smoothed cobbles on the beach or as larger nodules on the nearby farmland.

At basement level, the internal room partitions are also in masonry.

The internal walls on the ground floor and upper floors are formed in softwood stud work. This comprised substantial vertical wooden studs, onto which were nailed thin horizontal strips of willow, known as ‘lath’. This lath would then be covered in course lime plaster mixed with horse hair binder. On top of this would be spread an intermediate layer of plaster and, finally, a thin layer of fine plaster to provide a smooth and flat surface that could be decorated.

The floors are made from timber joists covered with wooden floorboards, while the roof is supported by timber rafters covered with close boards onto which the slates were nailed to keep out the rain.

Unlike the masonry, be it brick, render or bungaroosh, all of which could be found locally, timber for construction was imported, because most of the local trees had, by this time, been cut down to build ships.

To build Brunswick Town, almost all of the timber was imported from the Baltic states of north west Europe. Here, trees used to grow slowly and were much stronger than the modern, farmed, softwoods of today.

These Baltic timbers specified by the architect Busby were shipped across the North Sea to the port of Shoreham, then loaded onto ox-carts and drawn along the turnpike (todays seafront road) to the building sites of Brighton and Hove.

Cast iron was used to make the fireplaces, kitchen ranges, staircase balustrades, railings, balconies and rainwater pipes and hoppers. Much of this was produced locally, at ironworks in Brighton and Lewes.

The smooth wooden handrail is mahogany, imported from the tropics.

The paving slabs were quarried in south west England and shipped to Brighton and Hove.

A house like this one would have cost around £3,000, ‘finished complete’, with glass in the windows and fireplaces in the rooms, but the house would otherwise be bare.

Georgian families paid a premium to buy a house to the ‘preferred east side of a square’, where the sunlight shining in through the large front windows meant they would spend less on artificial lighting over the course of a season.