Gilding

Gilding is a decorative technique whereby an extremely thin layer of real gold is applied to the outside of an object such as a mirror frame, or the surface of a piece of interior detailing such as a cornice.

In many affluent Regency homes plaster decoration was frequently picked out in gilt, sometimes to excess. By the 1820s, the use of gilding on interior mouldings had begun to decline somewhat, but it continued to be used to enhance furniture woodwork and picture frames. Gilded lacquer work - classical gold motifs on a black background - was popular during the Regency.

Gilding is incredibly durable and will last indefinitely under normal conditions. Gold leaf today is prepared much as it has been for 4,000 years, although the gold leaf used by Regency gilders was considerably thicker than modern machine pressed leaf. Traditional manufacture of gold leaf began with a gold bar being melted down and cast in strips which then go continuously through rollers until extremely thin. At this point it was beaten by hand to further thinness between skins, then layered between sections of cattle's intestines - called ‘gold beaters' skins' - and beaten to its final thinness. By this stage, the gold was extremely flimsy, and had to be handled with pincers. The leaf with a thickness of 0.00001 mm was cut into 3 3/8” squares and sold in books of 25 sheets.

The surface to be gilded is first cleaned and smoothed. If the material is porous, such as plaster, shellac is applied to seal its surface. For burnished leaf gilding, the surface must next take a coat of rabbit skin glue size, followed by a coat of ‘gesso' a solution derived from boiled parchment cuttings mixed with gilder’s whiting, linseed oil or tallow. The gesso is next covered with Armenian bole, a red earth and pipe clay solution applied with a hog or camel hair brush. After receiving several coats of bole, the surface is then smoothed and burnished before the gold leaf is finally applied.

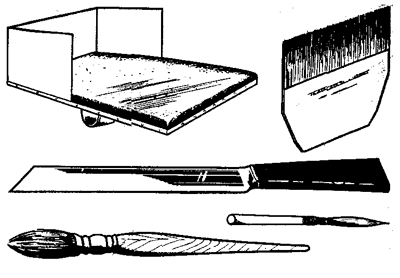

Above: A guilders tools.

The gold leaf is passed onto a gilder’s cushion and then manipulated to be reasonably flat. The prepared area is brushed with water and the gold leaf is picked up and placed on the prepared surface and firmly pressed down. To produce a burnished finish, the gold leaf is applied using the skilled ‘water gilding' method, in which the gold leaf and the gelatine based mordant which fixes it are applied simultaneously. After an hour or so, the gold leaf can then be burnished and sometimes a protective varnish is required. The gilt surface is finally burnished using an agate tipped tool. Other simpler forms of gilding are sometimes employed but they do not provide the brightness of the water gilding process described above.

Adverts placed in the Brighton Gazette during the 1820s, to sell newly finished Brunswick houses, can be found promote richly gilding dining rooms as an attractive feature of the home.

If you are interested in further reading on this topic, these links will provide you with more information: